Our Industry

The LMCT Represents Vast Portions Of The Mechanical Insulation Industry

Mechanical Insulation, a sometimes forgotten technology, is a core competency for commercial and industrial building construction.

It is a vital component in the design, construction, maintenance and renovation of commercial and industrial structures.

At a time when energy efficiency, environmental impact and social and economic demands on facility owners have never been greater, Mechanical Insulation provides actual positive results.

%

of all greenhouse gas emissions in the U.S

Multiple studies have revealed that buildings consume about 40 percent of U.S. energy demand, including 70 percent of the electricity and 12 percent of the potable water. Annually, they also produce roughly 40 percent of all greenhouse gas emissions in the U.S.

Making buildings more energy efficient is crucial to reducing America's energy consumption and to combat climate change.

Insulation is widely used at the residential level due to its efficiency benefits. However, the most significant untapped potential is in the commercial and industrial sectors, which, according to the Energy Information Administration, combine to consume 2.5 times more energy than homes.

Since its inception, the Mechanical Insulators Labor Management Cooperative Trust (LMCT) has advocated on behalf of the members of the International Association of Heat and Frost Insulators and Allied Workers, our affiliated contractors and the companies that manufacture Mechanical Insulation and Firestop products.

What Is Mechanical Insulation?

Mechanical Insulation is a proven energy efficiency and emission reduction technology that improves the working environment, reduces costs and increases the value of a building, while creating and preserving tens of thousands of green jobs.

Through increased use and proper maintenance of commercial and industrial insulation – collectively known as Mechanical Insulation – we have the potential to slash energy demand and greenhouse gas emissions in the manufacturing sector, while creating jobs.

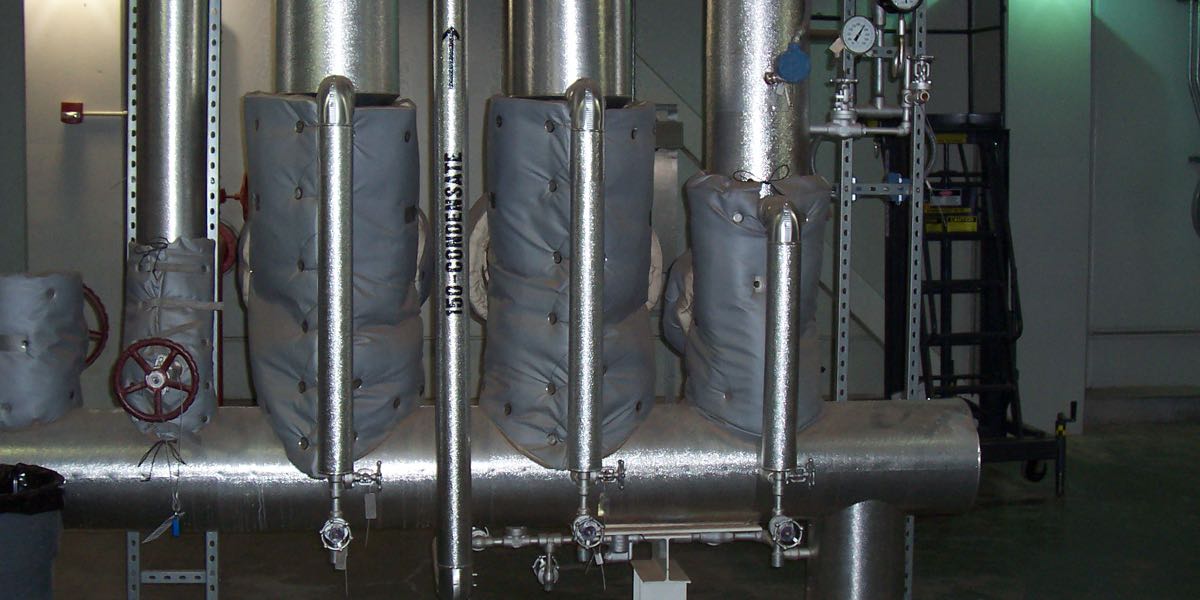

Mechanical Insulation systems are used on piping, equipment, vessels, HVAC, boilers and similar mechanical equipment. They are also used in piping applications in industrial and commercial systems and in above- and below-ambient service temperature conditions.

It is a vital component in creating and maintaining high-performance buildings. A high-performance building integrates and optimizes all major high-performance attributes on a life-cycle basis, including energy conservation, environmental, safety, security, durability, accessibility, cost-benefit, productivity, sustainability, functionality and operational considerations.

Improving energy efficiency is the first and most important step toward achieving sustainability in buildings and organizations. Energy efficiency helps control rising energy costs, reduces environmental footprints and increases the value and competitiveness of buildings.

In 2007, Congress created the Net Zero Energy Commercial Building Initiative (CBI) as part of the Energy Independence and Security Act.

The initiative’s goal is to “develop and disseminate technologies, practices, and policies for the establishment of zero-energy commercial buildings.” Net zero-energy buildings generate as much energy as they consume through efficiency technologies and on-site power generation.

Types of Mechanical Insulation

Mechanical Insulation is engineered and designed to be applied to mechanical systems. Often confused with insulation designed for walls and ceilings (the pink stuff), mechanical insulation is actually quite different. It helps a designed, engineered system function at a specific operating temperature to ensure it operates efficiently. Incorrectly installed Mechanical Insulation results in loss of operating expenses, wasted energy and unnecessary and harmful greenhouse gas emissions.

Maintenance/New Construction

Mechanical Insulation should be installed in new construction buildings/projects. It can also be retrofitted into existing buildings and facilities, as well. It is imperative that Mechanical Insulation be installed to the strict technical specifications developed by engineers and inspected to ensure it was installed within compliance. Mechanical Insulation must be maintained and inspected to ensure its effectiveness in the operation of the systems.

Industrial High Temperature

Extremely high-temperature Mechanical Insulation requires special attention due to the severity of its thermal operating range. Any loss of heat within the system can reduce its operational efficiency. Furthermore, heat generation is expensive, making energy efficiency paramount. New Mechanical Insulation technologies require the most highly trained workers to install these products professionally.

Pads And Blankets

Pads and blankets are quite popular with high-temperature systems where access to the equipment is available. They are typically used on flanged pipe or other equipment that requires insulation or personal protection. Removable and reusable pads offer a cost-effective solution to frequently serviced high-temperature equipment.

Storage Tanks and Vessels

The storage tanks and vessels in many industrial facilities may require insulation, which can be used in a number of applications. From traditional Mechanical Insulation to newer systems that include vertical panel systems, storage tanks and vessels can benefit from regulated temperatures. LMCT-affiliated contractors are highly proficient in these types of applications.

Boilers and Chillers

Both of these units operate at the extreme temperature range of Mechanical Insulation, as each type of unit has individual concerns that need to be addressed. For instance, a boiler has to be completely insulated to reduce extreme heat loss, while a chiller or refrigeration system requires vapor retarders and barriers to reduce rust and bacteria-causing condensation.

Metal Cladding/Weather Barriers

Metal cladding, usually aluminum, is designed to offer a strong weather barrier to protect the insulation from rain, snow, ultraviolet rays and physical abuse. Additionally, metal jacketing offers an attractive appearance, with a silver-like aluminum, which can be painted to a desired color. Metal finishes can be used indoors or outside.

Commercial Heating and Cooling

Within a typical building, miles of insulated piping deliver hot water, recirculated hot water and cold domestic water. This is probably the most common type of Mechanical Insulation most people encounter. It is also quite common for some of this Mechanical Insulation to be missing, which increases the building’s operating costs. Any missing or damaged Mechanical Insulation should be replaced.

HVAC Systems

Heating, Ventilating and Air Conditioning (HVAC) systems are used to heat and cool a building. The building’s delivery system can be a labyrinth of ductwork, which supplies or returns the conditioned air to its desired location. Duct insulation must be properly installed and maintained correctly to ensure its vapor barrier capabilities. Otherwise, unfavorable conditions will develop, such as condensation, which can spread to large distances and potentially stain ceiling tiles or drywall and lead to bacteria and mold growth.

Vapor Retarders and Barriers

This lesser-known aspect of Mechanical Insulation plays a large role in its performance. Barriers and vapor retarders separate a hot insulation application from a cool or cold application.

For instance, have you ever noticed how condensation forms on the outside of a cool beverage can on a hot day? The same thing happens with pipes and equipment if the vapor barrier is compromised. Once condensation is present, it will cause the metal components to rust, which in turn will limit the life of the system. When Mechanical Insulation gets wet, it does not function as well. It also creates an environment where mold and bacteria growth is prevalent.

CUI Programs

Corrosion under the Insulation, or CUI, is an administrative concern that addresses the lack of weather or vapor barriers. Many decision makers have realized that it is cheaper to have Mechanical Insulation professionally installed or maintained with a vapor barrier than to replace the pipe or equipment.

Mechanical Insulation Evaluations

Mechanical Insulation should be inspected periodically, and those performing the inspection should be highly trained to properly identify and assess any deficiencies within the insulation system.

A more thorough investigation could include an energy audit, which can calculate the amount of energy lost as a result of missing Mechanical Insulation and then analyze the data to calculate the amount of money lost, energy wasted and greenhouse gas emissions created. Thermal photography can also be used to show the deficiencies of any Mechanical Insulation system. These evaluations will demonstrate how properly installed or repaired Mechanical Insulation will provide a return on investment (ROI) within six months to two years, regardless of the size of the project. Also, a Mechanical Insulation Energy Audit can be used to help formulate a budget to address a facility’s insulation plan.

Asbestos Abatement

For 100 years, asbestos was used as an insulation material because it was a great insulator. Unfortunately, in the late 1970s, asbestos was declared to be a carcinogen. While the deadly fibers have not been used since that time, they may still be found in buildings built before 1980.

Asbestos is harmless until it is disturbed. Untrained workers often unknowingly damage asbestos insulation for various reasons, not knowing the dangers hidden within. While Mechanical Insulation must be maintained, insulation containing asbestos must be removed in order to protect workers and others from the dangerous cancer-causing mineral. Contractors performing this work are strictly licensed, as the work is highly regulated and inspected for the safety of the people who live or work in the building.

Firestop and Smokeseal

Commercial and industrial facilities are constructed to have fire-rated walls, which are designed to contain a fire if one breaks out in the structure, as required by both fire and building codes. However, fire-rated walls can be compromised during construction, as penetrations may weaken the wall’s integrity. If a fire occurs, a compromised wall may permit fire or smoke to penetrate through it and quickly spread to other parts of the building. A specialized Firestopping contractor will identify these “weakened” areas and install special materials to regain the wall’s fire-rated barrier. Sadly, the true value of this specialized industry is only realized after fire. This type of insulation has proven that it will save lives when properly installed.

Nuclear Specialized Applications

Installing Mechanical Insulation inside a nuclear power plant is a highly specialized skill, as specific types of insulation and installation techniques are required. These materials and techniques differ when compared to normal mechanical applications due to Nuclear Regulatory Commission (NRC) requirements. LMCT-affiliated contractors who perform this type of work employ a highly skilled workforce specifically trained to work inside these plants.

Specialized Insulations

Mechanical Insulation is used in many areas for different purposes, such as sound attenuation, which is a type of insulation used to reduce the transmission of sound. Insulation also plays an important role in the maritime industry, where it is installed on ships. Besides asbestos abatement, LMCT-affiliated contractors perform lead and mold remediation to keep people safe and healthy.

Highly Trained Workforce

The installation of Mechanical Insulation may appear simple, but it is rather complex, as there are many different types of Mechanical Insulation, each with different limitations and application processes.

LMCT-affiliated Mechanical Insulation contractors exclusively use a union workforce instructed through an intense apprenticeship program, which is registered with the U.S. Department of Labor and the Canadian Provincial Government. These workers receive additional journeymen update training throughout their careers to keep them up-to-date on the latest technology, tools and industry information. This makes them the most highly trained Mechanical Insulation workforce in the world.

Trained to Current Standards

Our affiliated contractors employ workers throughout the U.S. and Canada who are specifically trained in the latest safety technologies and practices, often exceeding standard OSHA regulations. This keeps them safe on the jobsite, reducing injuries and keeping projects on schedule.

Find an LMCT-affiliated Contractor

LMCT-affiliated contractors uphold a high standard of quality of work, as they pay for their employers to receive industry-leading instruction through a Department of Labor registered apprenticeship program. Discover the difference of trusting an LMCT-affiliated contractor on your next project.