Where To Start With Mechanical Insulation?

The Top 10 things you need to know about Mechanical Insulation to understand the industry better.

Lesson 1: The Specification

If the community in which the facility is being constructed has an energy code, be sure the specification for mechanical insulation meets or exceeds that code. Many, but not all, specifications adhere to ASHRAE 90.1, 2007.

Make sure the specification for Mechanical Insulation is taking into consideration the current environment. If you go cheap now you may pay dearly later.

The topic of Mechanical Insulation specifications is too large to cover on one webpage, but there are a few items that the owner should consider for a properly functioning facility. All domestic hot and cold water pipe systems should be properly insulated. Hot water systems should be insulated from the hot water heater or storage tank to the branch leading to the faucet.

Every foot of uninsulated hot water pipe translates into dollars out the window for the building owner. The lack of Mechanical Insulation on a 140-degree pipe system can become very expensive (see calculations in Lesson 2 below). Failure to insulate domestic cold water systems can create condensation on the pipes, which can cause unsafe conditions for walking and mold growth, which can be very expensive to eradicate.

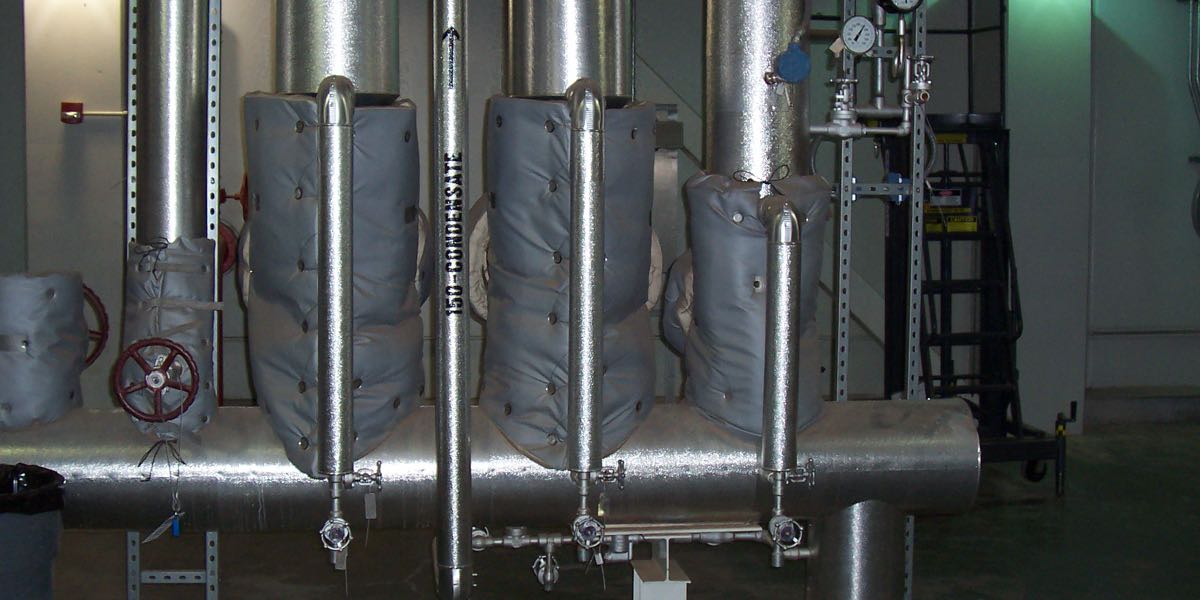

On heating systems, all hot water supply and return piping, steam and condensate piping, and process heating system piping should be properly insulated. This should include valves, strainers and fittings.

In the current national environment, more emphasis is placed on the reduction of greenhouse gases than the old economic thickness and payback theory.

Proper Mechanical Insulation of cooling systems will also show environmental impact.

Proper Mechanical Insulation on below-ambient cooling pipes will reduce the possibilities of mold growth and will lessen the chances of condensation problems as well as increase equipment efficiency.

Proper Mechanical Insulation on ventilation systems should be included in the specification. This should include the supply and, in many cases, the return duct systems.

Lesson 2: “Value Engineering”

Was the Mechanical Insulation for this facility “value engineered” or was someone trying to convince you that you should “value engineer” your Mechanical Insulation specification?

Value engineering, when it comes to Mechanical Insulation, almost always means that the insulation thickness was compromised, the materials were changed (a cheaper substitute) or the insulation was eliminated on some services or portion of services.

Value engineering is implemented to get the initial building cost at or below the fabricated number placed on the facility during the design stage.

The problem with “value engineering” Mechanical Insulation is that the cost to operate the building will increase as Mechanical Insulation is eliminated or reduced. When Mechanical Insulation is reduced, the equipment within a facility works harder thus increasing operating costs and decreasing the life of the equipment.

The process is almost never done with the long-term ramifications of the building operation in mind.

A case in point: A building owner or architect allows the specification for a 180-degree hot water heating system to be decreased from 1 ½” thick fiberglass material to 1” thick. There would be a small savings in material cost. The increase in CO2, NOx and CE emissions goes up 32 percent for each of these greenhouse gasses. The heat loss for the system goes up 32 percent and the cost per foot per year goes up 32 percent.

These numbers are just for reducing the insulation thickness.

Now imagine if portions of the system are not insulated at all.

Another case in point is when a building owner or architect allows the specification for a 140-degree domestic water system to decrease from 1 ½” thick fiberglass to 1” thick. The increase in CO2, NOx, and CE emissions goes up 28 percent. The heat loss for the system goes up 28 percent and the cost per foot per year goes up 28 percent.

Again, imagine that the system is not insulated at all due to “value engineering.” The elimination of Mechanical Insulation on domestic water systems is a frequent victim of “value engineering.”

If your facility was “value engineered” in the Mechanical Insulation portion of the building, you may well be paying for something you are not getting, and you will be paying for it for years to come.

Lesson 3: Mechanical Pipe, Duct and Equipment Installation

The proper installation of the mechanical services is of the utmost importance when dealing with mechanical insulation.

From the mechanical perspective, the fluid in the pipes gets to where it should, the air in the ducts gets to the diffusers, the toilets flush and the faucets work, so it is all good. If the pipes were installed too close together for the Mechanical Insulation to be installed properly it can become a big problem. If the pipe or conduit has been installed using the sheet metal duct as a support system it may require that the conduit and/or pipe be insulated with the duct.

A simple rule of thumb is that the outside edge of parallel pipes that require insulation should be at least double the insulation thickness plus one-half inch apart. If a duct system requires Mechanical Insulation, the electrician, fitter, plumber, cable installer or any other trade should not use the duct as a support system; the duct should be installed with enough clearance to insulate around the entire duct.

If pipes, ducts or equipment require Mechanical Insulation, they should be installed with enough clearance to allow for the proper installation of Mechanical Insulation materials.

Lesson 4: Materials

Make sure that the proper Mechanical Insulation is being installed on the specific mechanical service. Many materials look alike but are not similar.

Check the labels on the materials to ensure the proper thickness are on the jobsite ready for installation.

This can be accomplished by a quick walk-through of the facility. All major Mechanical Insulation manufacturers label their materials properly and you should be able to see the labels at a glance.

Lesson 5: Weather

Never force the Mechanical Insulation contractor to install material prior to establishing a dry building. If Mechanical Insulation is installed before the roof or windows are on the building, you may experience moisture-damaged insulation.

Wet Mechanical Insulation will support mold growth and reduce the effectiveness of those materials. If you force the insulation contractor to install material before the building is ready you are doing this at your risk. Highrise buildings frequently require Mechanical Insulation to begin on the lower floors while the upper floors are still under construction.

There are no windows or roof on the building, but the schedule requires completion on a certain date. This means the pressure is on to insulate now. Rain, snow and ice can enter the upper floors and melt down onto the materials that were installed on the lower floors.

This is a problem you do not want to deal with. In the industrial sector it is just the reality that material must be installed in inclement weather.

In most cases, however, the materials are protected immediately following insulation application.

Lesson 6: The Little Things

Look for little transgressions that can become big problems later. One such transgression is the lack of properly butting the Mechanical Insulation to one another as they are installed.

A small gap between the insulation sections may seem like a little thing, but this can become very expensive. If the gap is on a cold pipe system, it can allow for condensation to form on the pipe at the opening.

This can lead to mold growth on the Mechanical Insulation or on the ceiling where the condensation drips and forms a moist area for mold to grow. The dripping condensation can also lead to unsafe conditions on the floor where the moisture can collect and cause a slipping hazard.

Make sure the Mechanical Insulation is installed with properly butted joints and vapor barriers. Duct systems, too, can have the same types of problems as pipe systems with regard to this gap.

If it does not look clean and sharp when it is finished, it probably has not been installed properly.

On the hot side, the small gap is not as noticeable. It just allows for heat loss for the life of the building (see above Lesson 2). That heat loss translates to dollars out the window for the facility owner.

Lesson 7: Vapor Barriers

Vapor barriers are extremely important when insulating cold systems. Improperly installed vapor barriers can cost significantly when the failures become know to the owner.

Most pipe insulation materials are furnished with factory applied vapor barriers from the manufacturer. It is at the irregular surfaces that we see many failures of the vapor barrier system.

Cold Mechanical Insulation systems require a vapor barrier mastic to seal the fittings, valves, strainers, valve stems, etc. Look to see that small appurtenances are insulated to avoid condensation that can creep back into the main causing possible mold problems and dripping.

Ask to look at the mastic containers to ensure that the product is a vapor barrier material.

When the wrong mastic is used for the service, the costs to fix the problems can be very high.

It can include removing the old materials and replacing them with new materials.

This work can be very expensive and could involve removing and replacing portions of the ceilings and walls.

Make sure it is done right the first time.

Lesson 8: Pipe Supports

What are pipe support systems and what is the proper way to insulate them?

Pipes must be supported by hanger systems that are installed by the pipe fitting contractor.

There are many types of support systems but they all require some insulation between or over the pipe and hanger.

When walking through the facility pay particular attention to the pipe support systems on all services. Most specifications require some sort of insulation protection at the pipe supports.

There are many different systems to alleviate this pipe support problem. Insulation support saddles are designed to spread the weight of the pipe over a larger area at the hanger.

Wood plugs can be inserted between the insulation support saddle and the pipe.

Special treated wood saddles, half the diameter of the pipe, can be used between the pipe hanger and the insulation.

Heavy density materials can be installed at each pipe support to protect the insulation. Special insulation protection systems are manufactured by several companies that will support the pipe at the proper level while performing the insulation function required.

If there is no insulation protection saddle at the support the chances are good that the insulation will be crushed when liquid is placed in the pipes.

The crushing of the material will decrease the value of the insulation and may cause breaks in the vapor barrier which will allow for failure in the future.

The softer insulation type materials will usually require some sort of insert between the pipe and the protection saddle to spread the weight of the pipe over a large area.

If the insulation is showing signs of crushing, the chances are very good the inserts have not been installed. Large bore pipe sizes almost always require some sort of protection to insure that the insulation is not crushed.

Insulation protection inserts that are manufactured to size to address this problem. We frequently see copper pipes clamped directly to a unistrut hanger. The insulation can be field fabricated to go around and over most of the unistrut but not the portion that is in direct contact with the unistrut itself. That portion is destined to fail.

There are many manufacturers of special hangers that allow for proper spacing at the unistrut and allow for proper insulation.

Lesson 9: The Clean, Safe Job

Lesson 10: Flashings

One of the most important parts of an outdoor installation is the weather protection.

Many facilities use various gauges of metal products to protect the mechanical insulation from snow, rain, wind, ice and abuse.

If the protection fails, water may enter the mechanical insulation system and begin the process of corrosion on the pipes under the mechanical insulation as well as cause the failure of the material to perform as specified. Failure points can be found in many places on outdoor systems.

The lap of the jacketing on straight pipes should be facing down at four o’clock or eight o’clock. On risers, the lap should be away from the direction of the prevailing wind.

All joints should be overlapped by at least 3” to ensure that no moisture can be driven into the system. On risers, the circumferential lap from the piece of jacket above should be over the jacket below to ensure that water will flash away from the insulation system.

Valve bodies, elbows, tees and other areas where irregular insulation is used should be properly flashed so the water will run away from the system not into it.

The edge may be cleaner if the jacket is run up and over the downside of the elbow cover, but the moisture will run down and into the mechanical insulation system if this practice is used. Common sense should dictate how flashings are done.

If water will run into the system it is being done wrong. Caulking should be used at all appurtenances to keep moisture out of the system.

Insulated systems should not be used as a platform or ladder to access higher areas.

When people stand on weatherproofed material they can destroy the protection and allow for moisture to enter the system. There are many new weatherproofing materials on the market that not only provide weather protection but vapor barrier as well and they are gaining wide acceptance.

Find an LMCT-Affiliated Contractor

The LMCT partners with the Insulators Union throughout the U.S. and Canada performing high quality work in the following industries:

• Maintenance and New Construction

• Industrial High Temperature

• Pads and Blankets

• Storage Tanks and Vessels

• Boilers

• Chillers

• Metal Cladding/Weather Barriers

• Commercial Heating and Cooling

• Vapor retarders and barriers

• Asbestos abatement

• Firestop and Smokeseal

• Nuclear Specialized Applications

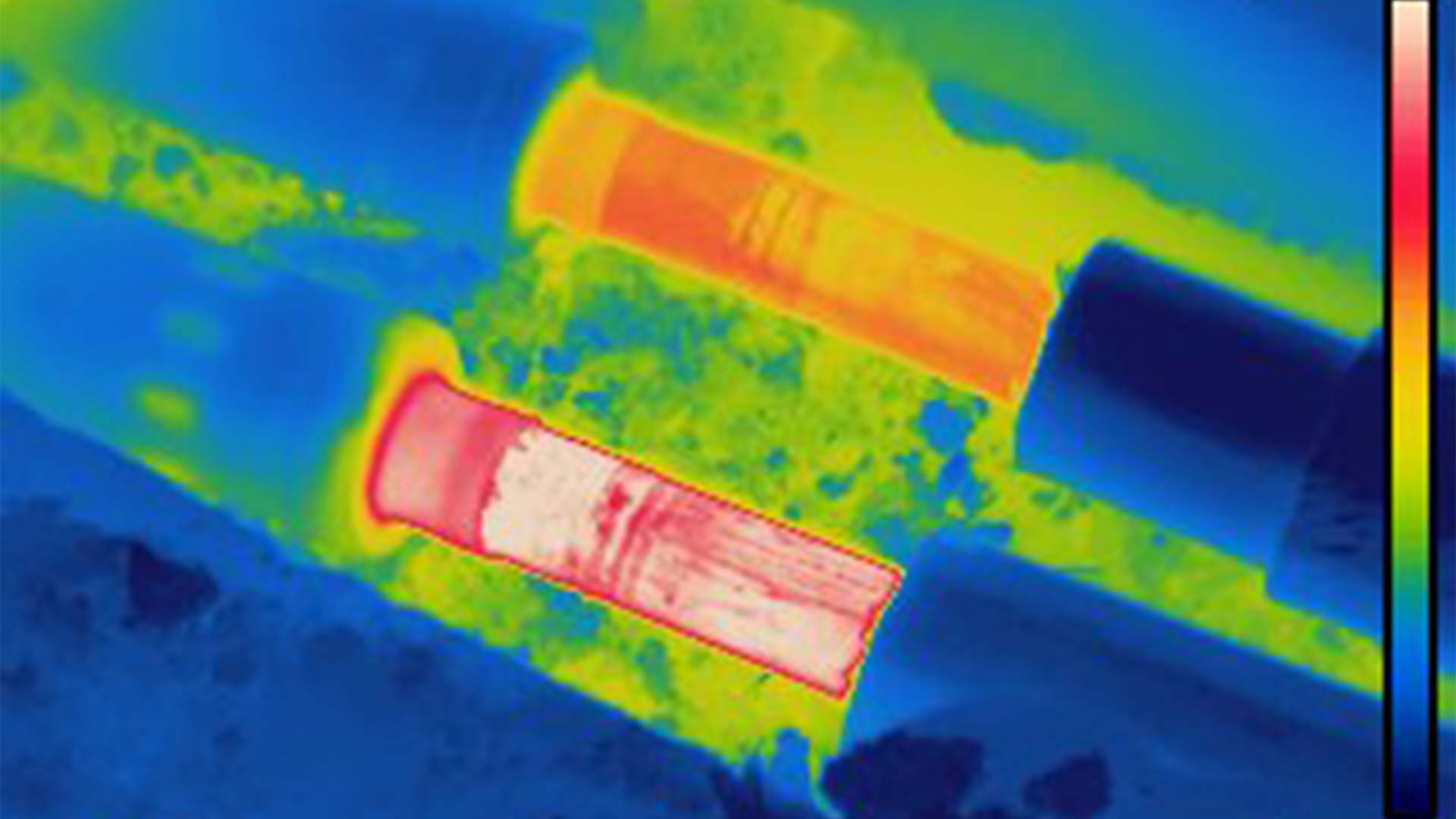

• Mechanical Insulation Evaluations

• CUI Programs

• Specialized Insulations